Bedlinen Production Process

We all know, it is very important to choose the right bed linens, If you want to create an excellent experience for your guests in hotels. And that can be your positive point as well.

Choosing the right linens requires a lot of search and experience. Not just that, it also creates a positive impact on your guest. So if you want to impress your guest, then look for the ideal material and exceptional manufacturing quality. This is the easiest way to get bed linens for your hotels.

Cotton Yarn Production

Cotton yarn is produced by spinning the fibers. The twisting method! It is simple, our grandmothers used to that by a wood hand tools 30 years ago.We basically put the fibers on top of each other than twist them by a certain number.

The keyword is the twisting number. That twisting number determines the softness and absorbency of the cotton yarn. Less twisted yarn means more bulky yarn. More bulky yarn means softer yarn. Softer yarn absorbency will be higher for sure. Fiber’s lengths are being between 12 mm and 57 mm in cotton fibers.

We have a combed process in yarn production that eliminates the short threads so we obtain only long threads in combed yarn. So Combed yarns have 30 mm and above fiber lengths. That is highly enough yarn quality to produce up to 400TC bed linens.

Thread Count

The term refers to the number of threads in one square inch; therefore as a general rule the higher the thread count the smoother the fabric. Unlike the general concept that prevails in the mind of people that the quality of bed linen depends on thread count.

We mostly sell below qualities for europian clients and they are available in all companies’ stocks.

- Ranforce ( Plain Weave) Bed Linens;145 TC and 160 TC

- Sateen ( 4/1 Weaving) Bed linens; 210 TC, 250 TC, 265 TC, 300 TC

- Percale ( Plain weave) Bed linens; 210 TC

For higher thread counts there must be order with higher quantities so we can make a fresh production.

We suggest our Hotel clients use 160 TC Ranforce bed linens for 3-4 star hotels and 210 TC Sateen bed linens for 5-star hotels.

There are some hotels that also want to buy higher thread counts to provide the best experience to their guests so we can suggest them to use 300 TC bed linens.

Weight

The quality of bed linens also depends on the weight and density of fiber. The weight of bed linen is independent of thread count.

Lightweight bed linens have thinner threads in comparison to thick threads, which are heavier. Keep this in mind that the heavier the threads are the more you will feel uncomfortable. Weight also depends on the yarn numbers used in bed linens such as Ne30/1, Ne40/1, Ne60/1… Higher numbers mean thin yarns so we prefer to use Ne60/1 combed cotton yarns for sateen bed linens.

Fabric Composition

Of Course, it must be Cotton. We also produce poly-cotton bed linens as well regarding any demand.

Poly-cotton bed linens are more durable. that’s why that is preferred in industrial bed linens.

To provide the ultimate luxurious and regal experience to your guests, keep a keen eye on the fabric composition. Fabric composition is all about knowing the difference between natural and synthetic fibers such as polyester.

This is the reason, the choice of fabric completely changes the impact and entire look of the hotel room.

Pure cotton and cotton rich are two top choices in bed linens for hotels. Both of these options are famous for their unique and excellent features.

Weave

Weave, as the name indicates, represents how the bed linen fabric is woven.

The most common types of weave include plain weave, Percale weave, and sateen weave.

- Plain weave or Ranforce Bed linens; which uses a crisscross pattern with a soft finish. They are mostly weaved between 140 -180 TC.

- Percale Bed linens; They also have the same pattern as plain bed linens but their Thread counts are higher (it is a little tighter than plain weave) such as 210 TC.

They are characterized by a matte finish and a crisp hand. Our high-end cotton, 210 TC percale linens are light and invigorating yet incredibly soft.Percale fabric is lighter in weight and more breathable making it perfect for summertime or warmer climates. Hotel rooms mostly being so hot.That’s why we get many requests for percale bed linens.

- Sateen Bed Linens are woven to create a silky smooth surface with a luminous sheen and is known for its luster and drape.

Sateen is usually a little thicker and more tightly woven. It has a soft, inviting touch, perfect to snuggle into bed with during the cold winter months.

Size

Just like it is essential to consider quality and type of fabric, size is also a critical factor to consider.Most of the time, beds are of standard size; therefore, use the bed linens that fit best to them.

However, in case of customizable sizes, keep their size in consideration to give a finished and elegant look to the bed.Another essential thing to consider in determining size is the depth of the mattress

Care Instructions

Your bed linens need care as well, like any other thing. To some, it may sound bizarre; however, care is needed during laundering. Here are some instructions that you should follow while washing the sheets.

- You should always wash before use. This is because the first wash removes stray fibers, softens the sheet and prepares cotton for a long-life.

- Use a gentle wash and spin cycle. Always wash beautiful natural fibres and whites on their own and never wash with synthetics. If possible, don’t overload your machine.

- Avoid fabric softeners which artificially coat natural fibers that need to breathe. With regular use, you will experience a softness, unlike any fabric softener.

- Make sure to wash them above 40 degrees.

- Don’t mix the light colors with the darker ones.

- If tumble drying, use a gentle setting and avoid overloading. Extreme or prolonged heat will dry natural fibers causing them to become brittle and lifeless over time. Natural drying is always best.

- The best time to iron is when bedding is slightly damp as it will be easier.

Color Identification

Make sure your bed linens are in contrast with the overall theme of your hotel room. Therefore the color of your bed linen is essential to factor.

Mostly the hotel goes with plain crispy white color as we all know white never goes wrong. Besides, other options include patterned and textured for a statement look or some colorful bed linen.

Towel Production Process

Woven fabrics are consist of warp and weft yarns in 2 dimensions, but terry towels are consist of in 3 dimensions with an additional pile yarn. 80 % volume of towels are pile yarn so pile yarn means towel quality: Softness, color, appearance, water absorbency etc. I will summarize the properties of the pile threads below.

- Pile yarns are usually 100 % cotton. it is used rarely in some other types of yarns like bamboo and viscose yarns.

- Pile threads usually are Ne 16/1, Ne 20/, and 24/1 for lightweight towels, on the other hand, they usually are Ne 16/2, Ne 20/2, Ne 12/1, and Ne 12/2 for high gsm towels and bathmats

- Two or more ply pile yarns are used when high quality is required such as absorbency, appearance, and resistance to pile lay.

- Industrial towels must be resistant to washing. Towels made with the double pile yarn has less pile height so their life is more than single pile yarn towels. That’s the way double pile yarns are preferred in industrial towels

- Towels weaved with yarn-dyed pile yarns are softer than solid-dyed towels. Of course, they are expensive.

Weight

All towels have a fabric weight under the reference of ”GSM”(Grams per Square Metre). Choosing the right gsm at the right price isn’t that easy. The higher GSM values indicate a higher thickness.How can a buyer decide which gsm of terry towels are suitable for their customers? Towels are classified by GSM such as Light Weight(200 – 450 GSM), Medium Weight(450 – 600 GSM), and Heavy Weight(700 – 800 GSM) but I will make a different classification. Here’s our guide to buying the towels at right gsm.

Industrial towels like a hotel and hospital towels should be long-lasting so it is better to choose a medium weight and double pile. I always offer to hotel towel buyers that 400-500 gsm towels which has 20/2 Carded pile yarn. Single pile yarn, Ne 16/1 is also another option for 360-450 gsm towels, if you are looking for low-cost towels.

Since bath towels are used once a day, there is no need to be a quick dry towel in the bath but it must be absorbent as much as possible for comfortable usage. Take a shower is an experience for people so everybody wants fluffy and soft towels. I prefer to use high gsm bath towels more than 500 gsm. On the other hand, hand towels must be quick dry as well as absorbent because they are used very often in daily life. They are also washed frequently.That’s the way high gsm towels are not preferred for hand towels, it is better to prefer 360-450 gsm for terry hand towels in dobby design.

Sculptured design towels must be of high weight to form the pattern well. 500-600 gsm is the minimum weight. Jacquard yarn dyed towels also must be more than 500 gsm because of the complicated designs. They are design based towels so high gsm is necessary to show the figures on towels.

Microcotton towels can be produced between 350-600 gsm. For more information, see my article about microcotton towels.

Velour towels weight usually are lower like 340-400 gsm. Velour towels are made by shearing the pile volume of 20%. More weight means more wastage so high gsm velour towels are really expensive.Their gsm could be up to 600 gsm.

High gsm terry fabrics are not preferred in Terry Bathrobes especially in hot countries like Greece. it is better to use 350-400 gsm terry fabrics for bathrobes. Pique fabrics are another option for lightweight fabrics. Pique fabrics are around 250-300 gsm.

We should destroy the general perception for towels that the high gsm the towel, the better it is. Sometimes the heavier weight towel such as the micro cotton towels has not well appearances after washing.

Whatever gsm of towel you choose, know that gsm will affect the cost of towel and quality. Ask me if you need any information about towel gsm and qualities

Used Yarn types

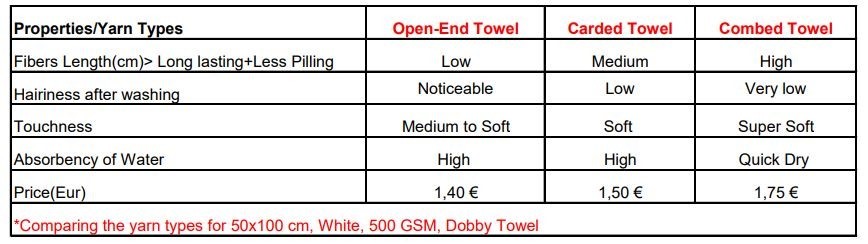

I mentioned in the previous article that many factors affect towel prices such as yarn, weaving and dying types. I will explain here only yarn types.

All terry towels are weaved from a ground warp, weft thread and a pile end. Warp, Weft and Pile yarn consumption in most towels are 20-20-80 percent respectively. That’s why my whole point is going to be about pile yarn properties in this article. There are 3 different yarn types are used in towel production. There are also another yarn types like air cotton and microcotton yarns but ı won’t go into them.

Combed Towels

Combed cotton yarn is a kind of yarn that has been combed to separate shorter fibers to make the yarn stronger and softer. Almost 12-15% of the cotton volume is removed by this way. Which results in a finer, stronger, higher-quality and more durable cotton yarn. It means a very soft yarns but slightly more expensive than carded yarns.

We prefer to use mostly combed yarns in luxury towels and bathrobes because towels are height-weight products in textile industry. That means it is really high cost raw metarial for regular towels. Combed yarns are usually preferred in men and women’s clothing and underwears.

Carded(Ring) Towels

Carded yarn production process is same as combed process but there is no ”Combing machine” to separate short fibers in spinning. That’s the way carded yarns has shorter fibers and more hairy appearence but carded yarns are the idael yarn type for terry towels.

- It is roughly 20% cheaper than combed yarns, it is economic. That is enough reason to be preferred in towels which are really heavy weight products.

- The shrinkage of carded yarn is higher than combed yarn but this property is not as important in the towels as it is in the clothes. I mean there won’t be a problem if the hand towel size is 50×95 cm instead of 50×100 cm after washing.

- Towels made by carded yarns are highly enough absorbent and quick dry.

- There is no difference between combed and carded yarns in the context of color fastness to light and color fastness to wash. On the other hand fastness to rubbing is less than combed yarns. Be careful! Fastness to rubbing is important in yarn dyed towels. Especially contrast colors like white-black yarn dyed towels

Open-End Towels

Open-end spinning is completly different from carded or combed spinning process. There is not a ring frame and winding process in open-end yarn production. That means open-end production rate is higher than carded yarn machines so open-end yarns are cheaper than carded or combed yarns. Open-end towel properties;

- There is no difference in the water absorption rate of ring spun and open-end terry towels.

- The abrasion resistance of open-end towels are lower than that of ring towels in both wet and dry states.

- Softness of ring towels are better than open-end towels. Be careful! open-end towels are looks like ring towels with chemical treatments like silicon. we can understand after washing if it is open-end towel or carded towel.

- Open-end towels are cheapest towels so it can be preferred in promotion towels.

I added above a representative table to see the differences of the towels produced from all kinds of yarn types. That table gives you an idea to make a decision on buying process. As a result combed towels are almost 20% more expensive than carded towels and carded towels are 10% more expensive than open-end towels.

Yarns used as pile

Pile height has a very important effect on the usage and comfort properties of terry fabrics. I will list briefly my notes below about the pile height. Pile Height varies between 2,5 mm and 9 mm. Notice that is not pile yarn consumption or pile densty.

- Pile height has the most significant effect on water absorption properties. High pile height means high weight.

- Doulble pile yarns (2/20’s, 2/24’si, 2/12’s) have less pile height than single pile yarsn( 1/12’s, 1/16’s, 1/20’s, 1/24’s)

- Short pile towels become long-lasting. Therefore, hospitality industry towels must have shorter pile height. We prefer to use for pile yarn 2/20’s to catch the optimum pile height for hospitality towels.

- Optimum pile height means smooth appearance on towel surface. You may have experienced at home that towels wrinkled and look like washed more than 100 times. This may be due to high pile height or low twist of yarns.

- Reaching enough pile height is important for sculpting design towels because the design can not seen clearly on towel surface, if there is not enough pile height. That’s the way sculpting design(Woven with high- and low-pile loops) towels weight must be more than 450 gsm or 500 gsm. Below towel may be an example of sculpting design towels.

Microcotton Towels

MicroCotton towel is produced in the same process as all weaving towels.

The only difference between MicroCotton Towels and Egyptian or Turkish cotton towels in production is the Cotton yarn which is the basic raw material for all towels.

MicroCotton towels are weaved by a zero-twist cotton yarn pile. On the contrary, other towels are weaved by a twisted yarn pile.

There is also another towel which is called ”soft-twist or low-twist towels” which is not a MicroCotton towel. Their pile yarn is a ring or combed yarn but has a low twist than an ordinary towel. That’s why soft-twist towels have a fluffy appearance and soft touches like MicroCotton towels.

But do not mix MicroCotton towel and Soft-twist towels. They are completely produced by different Cotton yarns.

So we need to know the Micro-Cotton yarns, their production process, and properties.

What Is Zero Twist Cotton Yarns?

Zero twist yarns are a special kind of yarn spun with no twist in its fibers. I know that is not possible in production. We can not use the cotton fibers without spun them in weaving looms.

There is a solution to keep the cotton fibers together with PVA yarn. We call this yarns Zero-twist yarns.

In comparison to products made using carded or combed cotton yarns, zero-twist weave products are the plushest, softest types of products. Highly absorbent yet it retains its softness after washing.

In comparison to products made using carded or combed cotton yarns, zero-twist weave products are the plushest, softest types of products. Highly absorbent yet it retains its softness after washing.

How Is Zero-Twist Cotton Yarn Produced?

The basic Cotton Yarn Production principle is twisting of the cotton fibers. Cotton yarn is produced in Ring spinning machine or Rotor( open-end) spinning machines.

For Towels pile yarn, Cotton Fibers are twisted between 300 and 600 times per meter in the Z-twist direction. Yarns are twisted because this gives towels extra strength and heavily-twisted yarns are particularly strong.

As a result, all cotton yarns must be twisted during production. Otherwise, the cotton fibers are dispersed during the weaving process so we can not use zero-twist yarns.

Less twisted the pile loops, the softer and more absorbent the towel in traditional towels.

Micro Cotton towels are made by a different spinning process from traditional yarns. As a result, the pile yarns remains untwisted

Here is a great solution to use zero-twist yarns in towels weaving.

There is a Synthetic yarn which is called PVA (Polyvinyl Alcohol) It is a water-soluble synthetic polymer.

PVA filaments wrapped on the surface of non-twisted cotton bundles to constitute a wrapped yarn.

A twisted cotton pile yarn is wrapped with a PVA yarn in the opposite direction(S-twist) of the cotton yarn. The opposite twist number is the same twist number as the original cotton yarn so the cotton yarn becomes zero-twist yarn.

PVA yarn covers the cotton yarn(untwisted pile) to reinforce the weaving process. Otherwise, it is not possible to weave towels with zero-twist yarns.

On the other hand, the sizing process is not necessary for Cotton/PVA yarn for the towels before weaving. Sizing is required to reinforce the yarns because yarns are exposed to friction during weaving.

PVA is dissolved in the water so that the terry is in a state of the fluffy fabric.

We call also this yarns; Twistless Cotton, Zero Twist cotton or air cotton.

What are the main advantages of MicroCotton towels?

Zero Twist or MicroCotton towels have a soft-touch quality and fluffy appearance.

The thickness of the twistless towels is higher. This is shown that twistless towels are more bulky and softer than that of normal towels. It offers a thick and luxurious towel ambiances.

You may concern about their durability. Their useful life is enough long both for homes and industrial products like the hotel and hospital towels.

Abrasion resistance of twistless towels is lower in comparison to that of normal towels. So it must be dried in the low tumble dry.

Pile pulling force of twist-less towels is lower than that of normal twist towels.

Properties relating to water absorbency in terms of rate of water absorption, ie, sinking time, capacity to absorb water in terms of water retention and surface water absorption are better in twistless towels than that of normal towels.